A 3D printer that makes metal structures appear out of thin air will attempt its hand at constructing — wait, printing — a pedestrian bridge!

MX3D is a Netherlands-based startup that researches and develops 3D printing technologies. Later this year the company is planning its most formidable challenge yet: Using 3D printers to construct a bridge over a canal in the heart of Amsterdam.

Make Me a Bridge

The MX3D crew essentially takes everything about 3D printing and turns it on its head. The conventional process would be this: Printers build objects from the bottom up by applying layer after layer of plastic goop from dispenser that shuttles backwards and forwards along a horizontal plane. The finished product has telltale layers that sort of resemble a topographic map.

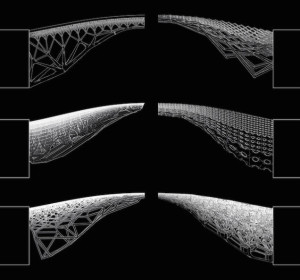

This isn’t how MX3D printers work. Instead, the MX3D-Metal printer prints structures by ejecting small amounts of molten metal via a welding nozzle at the end of a 6-axis robotic arm — it can craft objects from any angle, rather than simply along a horizontal plane. As molten steel flows via the nozzle, it quickly cools and sets, which allows the printer to produce straight lines, spirals or any other form for that matter, out of ‘thin air.’

“3D printing like this is still unexplored territory and leads to a new form language that isn’t bound by additive layers. This method makes it possible to create 3D objects in almost any size and shape,” wrote MX3D on its site.

You can get a close look at the metallic printer in the following Youtube video:

New Frontier

For their bridge, the team plans to make use of two teams of two robots. The teams would begin on opposite sides of the canal and build till they meet in the center, constructing their own supports along the way while moving ahead on movable platform bases.

The final design of the bridge and its exact location are still to be decided, however construction is being anticipated to start in September.

The venture is about much more than just a bridge; it might serve as a glimpse into what future construction sites would possibly look like. Rather than workers in hard hats and neon orange vests, autonomous 3D printers could be the new norm. If we are able to 3D print a bridge, why not make a skyscraper with 3D printing cranes? The MX3D group appears to agree with the broader influence their bridge project may have, as they state on the project website:

This bridge will show how 3D printing finally enters the world of large-scale, functional objects and sustainable materials while allowing unprecedented freedom of form. The symbolism of the bridge is a beautiful metaphor to connect the technology of the future with the old city, in a way that brings out the best of both worlds.

Although MX3D has tested their bridge-printing robots on smaller scales, they will possibly face a number of new challenges once the project gets going. Their robots must deal with irregular terrain, changing weather conditions and other factors which are usually controlled within the lab.

We will have to wait and see if MX3D’s bridge results in new potentialities for the technology, or if they merely ended up building a bridge to nowhere.

[…] You May Like: In Amsterdam: 3D Printing a Metal Bridge […]